Project Poldark

Donation protected

The Covid lockdown greatly affected us & we have been closed ever since.

We are a UNESCO World Heritage location with our very own unique Bronze Age Scheduled Ancient Monument to tin working which we call “Tin Henge”

Tin from the river bed has been worked here on the Trenear Mortar Outcrop for circa three and a half thousand years!

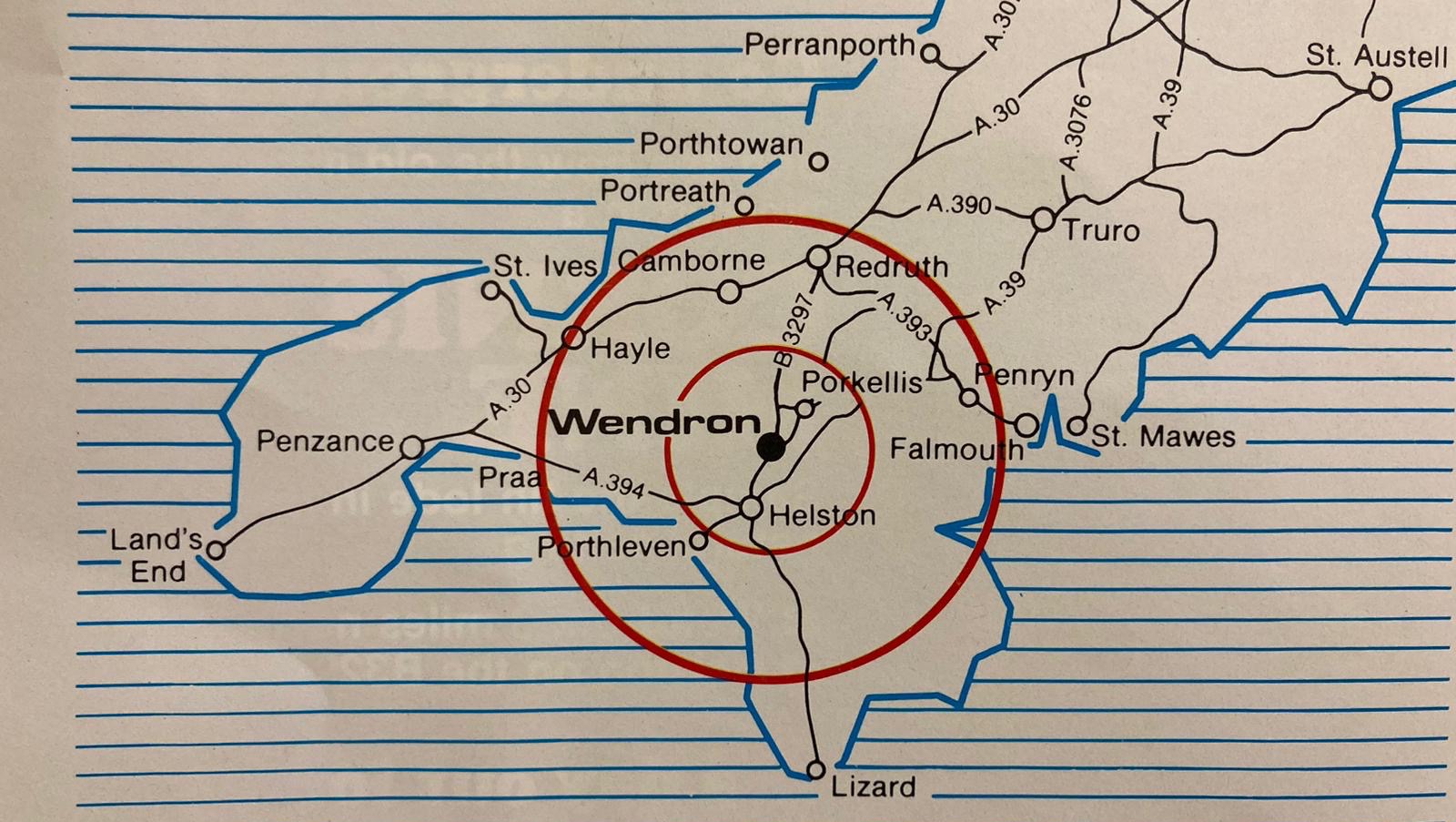

The mine and museum are set in pleasant waterside gardens in a wooded rural location in the very centre of West Cornwall.

Our late founder described the place as ‘a little piece of heaven on the B3297’.

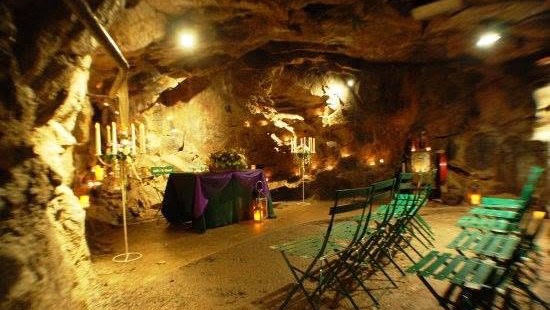

The former chairman of English heritage described our mine tour as ‘One of the two most atmospheric mine tours in Europe’

The ancient 18th century Wheal Roots Mine was renamed in 1976 by Winston Graham MBE author of the twelve Poldark books.

The popular BBC Television Poldark drama used the mine as a location for the two original series in 1975 and 1977.

The most recent BBC Television Poldark Series also used the mine as a location for underground filming.

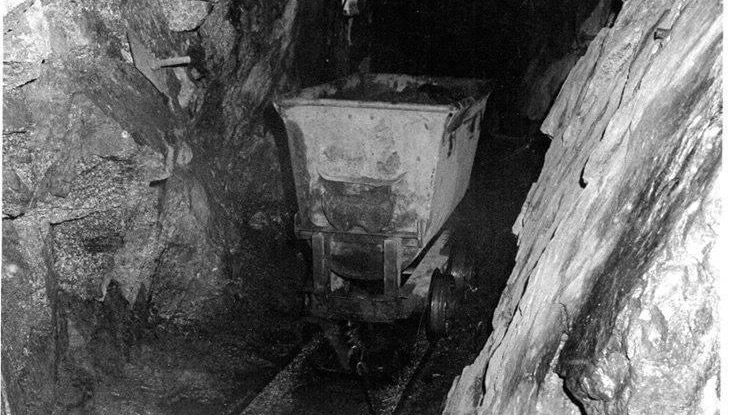

The mine has been used for location filming many times as it’s the only complete & genuine underground mine that can be visited by the general public in Cornwall.

The mine usually pumps 25 million gallons of water annually to allow access to the four levels of the old workings.

The pumps were turned off in 2020 due to the Covid Lockdown

In order for us to reopen after being forcibly shut 4 years ago, stage 1 of our plan is to open the museum, monument and gardens, we need to raise approximately £100,000 for general repairs to the museum & buildings and to bring the gardens back up to standard.

We hope to raise further funds in order to reopen the mine in stage 2.

One of our major costs is electricity, and we propose to build our own hydroelectric power source using a pre-established mile and a half long waterway, dating from the 13th century built by Cistercian monks from St Mary’s Abbey, Rewley, Oxford.

For us to complete this, we need to carry out critical repairs to the waterway as well as the installation of a hydroelectric turbine.

Although we have been closed, our volunteers have continued to work and we have been collecting objects for the museum.

The museum is not strictly a mining museum, it incorporates a broader history of the Cornish people and the industrial history of Cornwall which naturally covers tin and copper mining, where Cornwall once was the world’s leading source of those metals.

The museum sets out to demonstrate the myriad uses of tin and copper.

From communications to organ pipes together with early and more modern technology, we call this Techno Tin and copper.

In broad terms, we have identified 6 elements in order to reopen:

1. We need to establish our own mini hydroelectric scheme, this involves repairing and restoring our mile and a half long aqueduct (leat). The leat has been breached in 3 or 4 places which are difficult to access. We need the work to be done professionally so that we are guaranteed the flow of water insofar as we can. We would then need to build headstocks and purchase a suitable turbine generator (there are serval types), we have an approximate 20 foot head of water which will determine the best type of turbine for our particular application. We propose to install it in the water mill. The cost of repairs to the leat is approximately £15,000, the turbine and the associated works required will be about £50,000.

2. In order to enhance the visitor experience in the gardens, we feel it is appropriate to get the water wheel working again and that will cost approximately £5,000. The wheel was made in 1904 by Redruth foundry for the Treamble Iron and Fullers Earth mine on the Atlantic coast. It is smaller than the original wheel, which we might replace in future years. Getting the leat restored will facilitate the operation of the wheel.

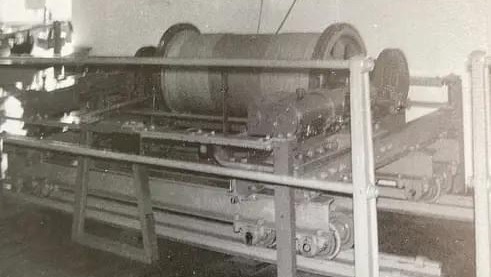

3. The restoration of the Morgans’s patented traversing winder. This was built in 1895 and taken to Paris to demonstrate the principal of the patent. It’s unique and built to a scale approximately 1/6th of the actual engine at Williams’s shaft, Dolcoath mine. Not a true model but a prototype, it was shown by Holman Brothers at the 1900 Paris Exposition, visited by 63 million people. We recently discovered some missing parts, including its original rails, these will be fitted to the engine and will be in an enclosed building, and is intended to be operated on compressed air.

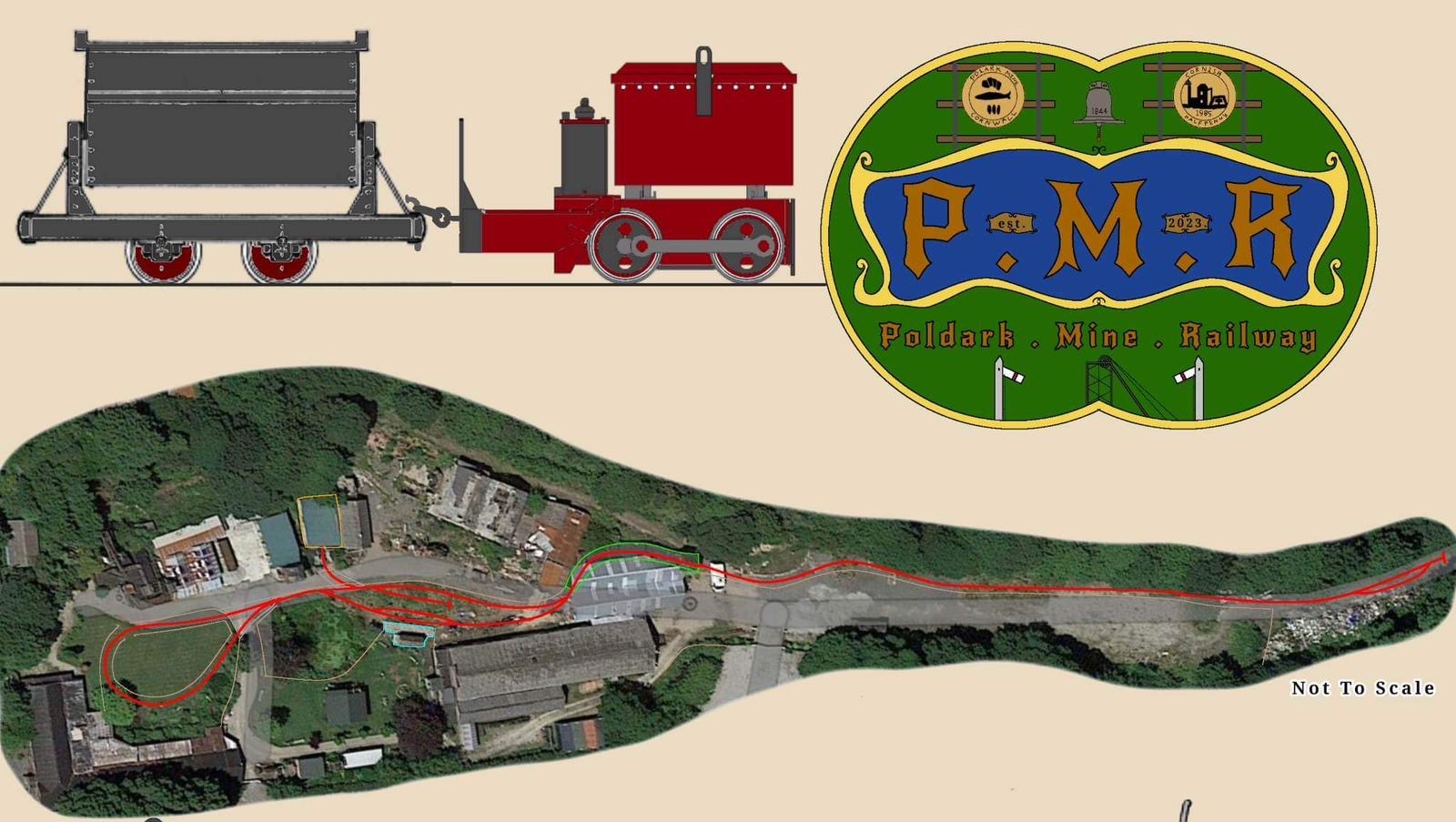

4. Demonstration Tramway. We are in the process of creating a 2 foot gauge tramway through the grounds to demonstrate some of our ten mining skips and other vehicles. One of our two Wingrove and Roger’s BEV battery electric mine locomotives is being restored, in order to achieve this, a new set of batteries is required.

We have 50 old cells in stock which will be used as scrap to offset the cost of the new ones.

The rail vehicles we have to demonstrate are from the following mines:

-South Crofty

-Geevor

-Dolcoath

-Robinson’s tramway

The loco, a waggon and a flat bed came from Clogau gold mine in North Wales (Where the late Queen Mother’s wedding ring’s gold came from).

We hope to use the tramway to demonstrate these vehicles around the gardens and to enable the moving of heavy materials and waste. It’ll be approximately be half a mile in length. Ultimately we would like to extend the tramway into the mine to join with the existing tramway.

5. The restoration of the Bunney Tin Mine beam engine. It’s currently arranged to work on an hydraulic system which is noisy and intrusive to our visitors. Therefore it is our intention to restore it to work on compressed air.

Ultimately we would like to have it operating under steam but the cost of that would be substantial.

The engine needs attention to its bearings and complete repainting, the approximate costs of this, including scaffolding, is £10,000.

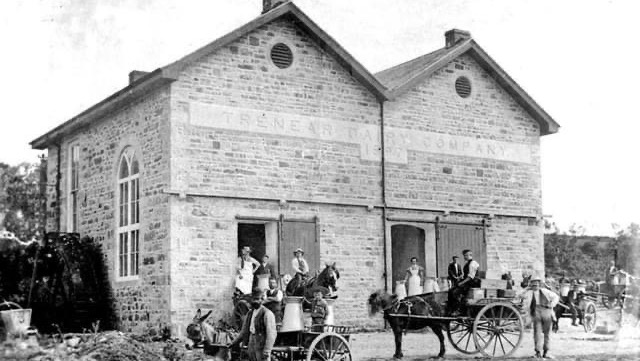

6. The plan is then to start restoration of the various buildings, the first one being the stone built water mill, as extended by the Trenear Dairy Company in 1897.

The left hand side of this building was the original location of the tin stamps established here in the late 13th century. It was converted and doubled in size by the dairy company. The original tin stamps had two water wheels one on either side and one pit remains to this day. It is our intention to put the turbine into the right hand side where the second water wheel once existed. This will provide a new point of interest for visitors. The rest of the building will become a visitor exhibition space. This is the only substantial stone building on the grounds.

The building needs a complete renovation including a new roof, it makes an excellent backdrop to the gardens.

The dairy Compressor House is a small building nearby, which we intend to turn back into a compressor house, installing the two compressors we already have which came from the government WWI nitrate plant at Billington On Sea. These compressors were used by the Company Tube Alloys Limited, which was a code name for the UK’s nuclear research project. The works also produced high octane fuel for the royal airforce in WWII.

One compressor is driven by GEC 600 Volt DC electric motor which is linked to an Bellis and Morcom two stage compressor. The second compressor by Reavall and Co of Ipswich is a single stage compressor driven by a Reader steam engine. Reavall later became part of Holman Brothers. Both compressors were presented to the museum in 1972 by ICI Limited.

We have many other projects on the grounds including the mine proper, which we will develop in subsequent years.

We hope that our project will receive your support.

Our team of volunteers appreciate your interest in this Cornish project, Poldark Tin Mine and The Cornish National Heritage Collection.

Organiser

Poldark Mine

Organiser