Save a WWII-era South Bend Lathe

Donation protected

Hi. My name is Tom Utley. I'd like to ask you to help me save a WWII-era machine tool from the scrap heap.

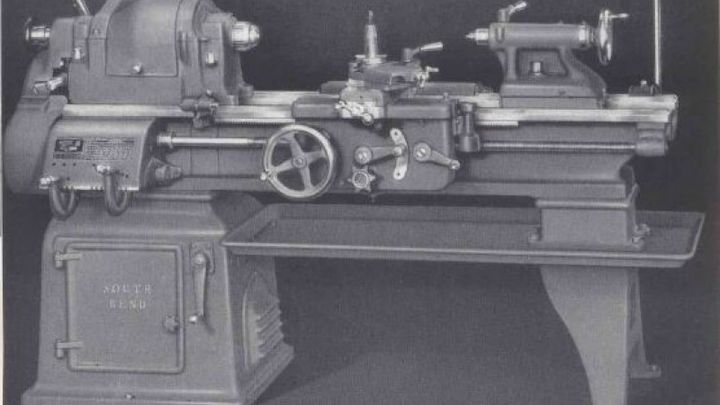

For the past 8 months, I've spent the better part of 400 hours restoring a very special 1943 South Bend 16" x 60" metal lathe. I purchased it from the estate of the prior owner, recently deceased, for $800 thinking I was getting a fair deal. It was in pretty rough but running condition. I knew it needed a lot of work, but the reality is I underestimated the amount of and type of work that it would require to get it back to good working condition. I've gone about as far as elbow grease and my original budget of $2500 can take me. The project has stalled now at a point where I need some professional work done that I simply can't afford on my own right now.

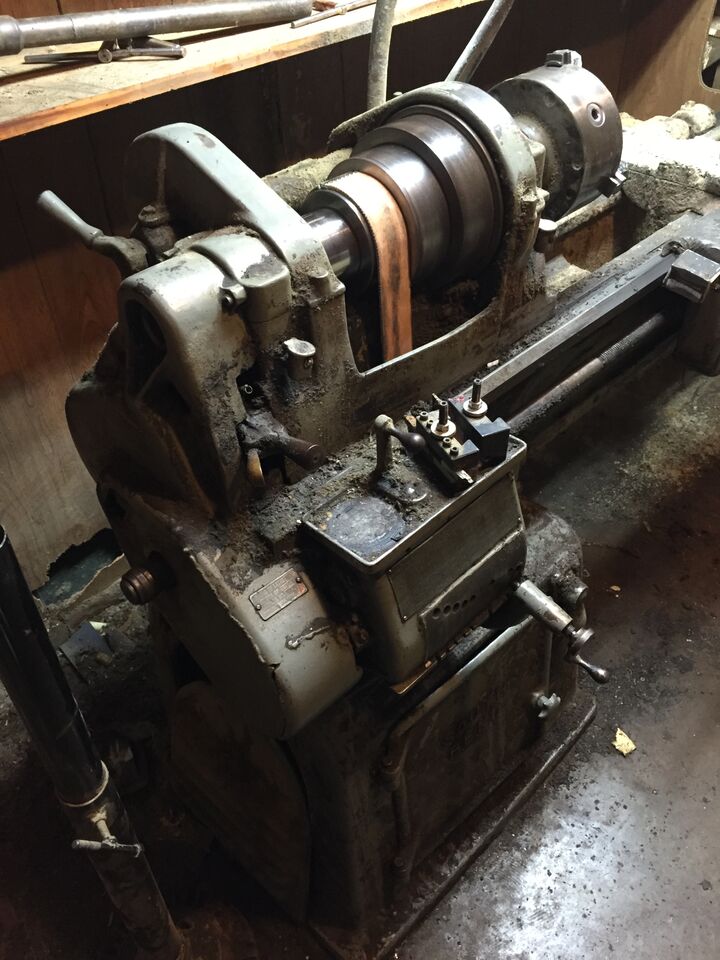

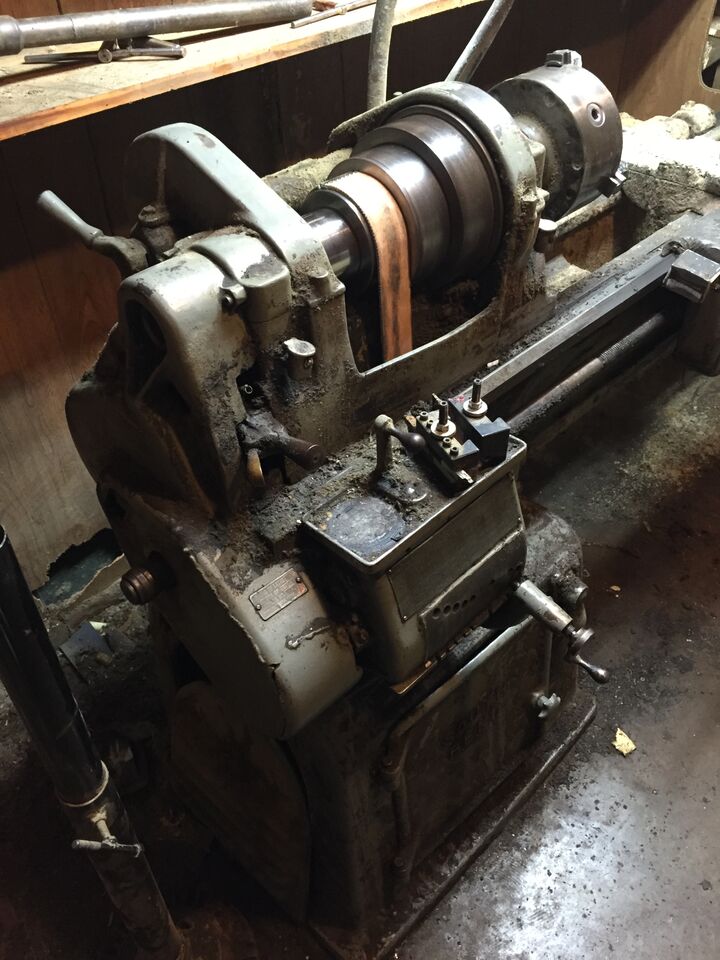

The following photos are of the machine as it came to me in January 2015:

Since then, I've stripped it down to the very last set screw, removed bucketloads of grease, grime, metal chips, and multiple layers of paint. I've de-rusted the cast iron, painted all the cast surfaces, polished all the machined surfaces, and installed new bearings as well as a new drive motor.

Since then, I've stripped it down to the very last set screw, removed bucketloads of grease, grime, metal chips, and multiple layers of paint. I've de-rusted the cast iron, painted all the cast surfaces, polished all the machined surfaces, and installed new bearings as well as a new drive motor.

Here are a few of the after photos--I think you'll agree it's a pretty startling transformation and I hope my enthusiasm shows through.

This last "after" video shows the new motor and countershaft assembly running on the VFD for the first time. I let it run for a couple of hours at full speed to break in the new bearings and make sure everything was playing well together.

Not shown here are another couple hundred gears, bushings, screws, dials, knobs, and shafts that make everything move under power. To tool nerds like me, they're all beautiful.

Throughout the entire project, I've been keeping a very detailed restoration log online. If you're interested in this sort of thing, by all means go read the full story using the link below. In it, I explain where the machine came from (a pool hall), its history starting in June, 1943, and the two-steps-forward, one-step-back process I've gone through to get it this far.

The resto log captures every wart, lesson learned, and eureka moment along the way. I've written it expressly for others who might be afraid to tackle a project this challenging so they feel empowered to save more of these wonderful old machines. Machines like this built the U.S., our military, and our powerhouse economy before we started offshoring everything. The log has been well-received, with over 14,000 visits so far and a lot of great feedback from other restorers. You can read the log here:

Practical Machinist South Bend Forum Restoration Log

Over its 72-year life, the machine was used first by the U.S. Army at Ft. McHenry, MD and later by NASA here in nearby Huntsville, AL. In 1984 it was purchased by a local gentleman named Bobby Callahan to make and repair wooden billiard cues. The seven decades of use took their tool, and now the machine is not capable of turning a straight cylinder.

In order to fix the machine correctly, the precision sliding surfaces (called "ways" in machinist-speak) must be re-ground so they are once again flat, level, and parallel with each other. Due to its large size--the bed alone is eight feet long and weighs around 1,000 lbs--the relatively few companies capable of doing the work are few and they are all very expensive because they usually service only heavy industry, not guys like me working out of their home shops.

Quotes I've received to grind and re-fit all the sliding surfaces properly are coming in around $3,000 plus freight costs to places like Milwaukee, Chicago, and Houston. Once the regrinding/refitting is complete, I still need another $1500-$2000 to buy missing accessories such as a collet closer, a new toolpost and tool holders, and a chip pan to catch the oily chips as they fall from the workpiece.

If I could afford to keep going with the project, I'd happily do so to keep this old girl running for another 70 years and pass it down to my son and his son, too. Unfortunately, I'm at a point financially where I need to either set it aside in the corner for a couple of years or I need to let it go to another sentimental tool fan who can afford to finish the job.

Thanks so much for considering my efforts to save what I believe is a piece of American manufacturing history and share it with others.

Tom Utley

Madison, AL

September, 2015

For the past 8 months, I've spent the better part of 400 hours restoring a very special 1943 South Bend 16" x 60" metal lathe. I purchased it from the estate of the prior owner, recently deceased, for $800 thinking I was getting a fair deal. It was in pretty rough but running condition. I knew it needed a lot of work, but the reality is I underestimated the amount of and type of work that it would require to get it back to good working condition. I've gone about as far as elbow grease and my original budget of $2500 can take me. The project has stalled now at a point where I need some professional work done that I simply can't afford on my own right now.

The following photos are of the machine as it came to me in January 2015:

Since then, I've stripped it down to the very last set screw, removed bucketloads of grease, grime, metal chips, and multiple layers of paint. I've de-rusted the cast iron, painted all the cast surfaces, polished all the machined surfaces, and installed new bearings as well as a new drive motor.

Since then, I've stripped it down to the very last set screw, removed bucketloads of grease, grime, metal chips, and multiple layers of paint. I've de-rusted the cast iron, painted all the cast surfaces, polished all the machined surfaces, and installed new bearings as well as a new drive motor.Here are a few of the after photos--I think you'll agree it's a pretty startling transformation and I hope my enthusiasm shows through.

This last "after" video shows the new motor and countershaft assembly running on the VFD for the first time. I let it run for a couple of hours at full speed to break in the new bearings and make sure everything was playing well together.

Not shown here are another couple hundred gears, bushings, screws, dials, knobs, and shafts that make everything move under power. To tool nerds like me, they're all beautiful.

Throughout the entire project, I've been keeping a very detailed restoration log online. If you're interested in this sort of thing, by all means go read the full story using the link below. In it, I explain where the machine came from (a pool hall), its history starting in June, 1943, and the two-steps-forward, one-step-back process I've gone through to get it this far.

The resto log captures every wart, lesson learned, and eureka moment along the way. I've written it expressly for others who might be afraid to tackle a project this challenging so they feel empowered to save more of these wonderful old machines. Machines like this built the U.S., our military, and our powerhouse economy before we started offshoring everything. The log has been well-received, with over 14,000 visits so far and a lot of great feedback from other restorers. You can read the log here:

Practical Machinist South Bend Forum Restoration Log

Over its 72-year life, the machine was used first by the U.S. Army at Ft. McHenry, MD and later by NASA here in nearby Huntsville, AL. In 1984 it was purchased by a local gentleman named Bobby Callahan to make and repair wooden billiard cues. The seven decades of use took their tool, and now the machine is not capable of turning a straight cylinder.

In order to fix the machine correctly, the precision sliding surfaces (called "ways" in machinist-speak) must be re-ground so they are once again flat, level, and parallel with each other. Due to its large size--the bed alone is eight feet long and weighs around 1,000 lbs--the relatively few companies capable of doing the work are few and they are all very expensive because they usually service only heavy industry, not guys like me working out of their home shops.

Quotes I've received to grind and re-fit all the sliding surfaces properly are coming in around $3,000 plus freight costs to places like Milwaukee, Chicago, and Houston. Once the regrinding/refitting is complete, I still need another $1500-$2000 to buy missing accessories such as a collet closer, a new toolpost and tool holders, and a chip pan to catch the oily chips as they fall from the workpiece.

If I could afford to keep going with the project, I'd happily do so to keep this old girl running for another 70 years and pass it down to my son and his son, too. Unfortunately, I'm at a point financially where I need to either set it aside in the corner for a couple of years or I need to let it go to another sentimental tool fan who can afford to finish the job.

Thanks so much for considering my efforts to save what I believe is a piece of American manufacturing history and share it with others.

Tom Utley

Madison, AL

September, 2015

Organiser

Tom Utley

Organiser

Madison, AL